Different types of Stainless Steel

DIFFERENT TYPES OF STAINLESS STEEL

Introduction

As we know about Stainless steel is gernic term used to represent the family of

corrosion resistance alloys. Did you know Like steel, stainless steels

are relatively poor conductors of electricity. We all know that Stainless

steel can be rolled into sheet, plates, bars, wire, and tubing. These can be

used in cookware, cutlery, surgical instrument, vehicles, construction material in large

buildings, industrial equipment, and storage tanks and tankers for chemicals and

food products. So today we are going to know about types of stainless

steel and what the uses of these are.

Different

Types of Stainless Steel

- Ferritic

stainless steel

- Austenitic

stainless steel

- Martensitic

stainless steel

- Duplex

stainless steel

- Precipitation

hardening stainless steel

Ferritic

stainless steel (https://www.instagram.com/p/Cg1NlIjhwnl/?igshid=YmMyMTA2M2Y=

)

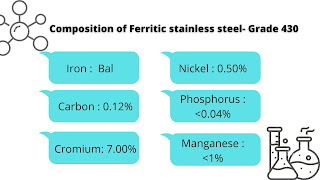

ferritic stainless steels, carbon is kept to low levels and the chromium content can range from 10.50

to 30.00%. ferritic stainless steels contain primarily ferritic microstructures at all temperatures and cannot be hardened

through heat treating and quenching. Stainless steel grade

430 is a non-hardenable steel containing

straight chromium, and belongs to the ferritic group of steels. Stainless steel grade 430 is known for its good corrosion resistance

and formability, coupled with practical mechanical properties.

Now that you have a basic

understanding of how Ferritic steel alloys differ from other varieties of stainless

steel, you are probably curious about how this affects the performance of

ferritic steel. There are some properties to be aware of.

Properties of Ferritic Stainless Steels

STAINLESS GRADES WHICH HAVE GOOD DUCTILITY AND

FORMABILITY

Carbon is what gives steel its hardness — yet

carbon also contributes to making steel more brittle and less ductile. Because

ferritic steel contains low carbon levels — as little as 0.03 percent — they

tend to possess above average ductility. As a result, ferritic steels can be

shaped extensively without risk of weakening.

The low carbon content of ferritic steels also gives them

excellent formability properties, meaning they can be formed into various

shapes without encountering problems such as necking or cracking.

The benefits of ferritic steel's low-carbon composition

do come with certain trade-offs to be aware of. For instance, ferritic steels

cannot be hardened through heat treatment. Furthermore, certain types of

ferritic steel may exhibit problems when welded — for instance, unwanted

cracking along the heat-affect zone.

TYPES OF STAINLESS EXHIBITING LOW THERMAL EXPANSION

Another key benefit of ferritic steels is their naturally

low coefficient of thermal expansion. This simply indicates the fact that ferritic

steels will undergo less expansion as they take on heat. Instead, the metal

will retain its fixed dimension much more readily. As you can imagine, this

property is especially important for metals that will be used for

high-temperature applications.

STAINLESS KNOWN TO HAVE HIGH THERMAL CONDUCTIVITY

Ferritic steels demonstrate excellent thermal

conductivity attributes, meaning they allow heat to move efficiently through

them. As a result, ferritic steels are a popular choice for furnace and boiler

heat exchangers, and other applications involving the transfer of heat.

STAINLESS STEEL WITH HIGH OXIDATION RESISTANCE

Finally, ferritic stainless steel exhibits a stellar degree

of resistance to oxidation, especially at high temperatures. This resistance

has to do with the formation of a protective chromium-oxide film on the surface

of the steel. Manufacturers can improve oxidation resistance even more by

including aluminum and/or silicon when producing ferritic steel.

The most common uses of ferritic stainless steel are the following:

- As part of automotive exhaust system silencers, automotive tubing, and catalytic converter casings.

- Interiors of appliances, particularly washing machine drums, kitchen

sinks, dishwashers, and some cooking utensils

- Water tanks, solar water heaters, and microwave oven elements

Austenitic

stainless steel

(https://www.instagram.com/p/Cg1NlIjhwnl/?igshid=YmMyMTA2M2Y=)

Austenitic stainless steels are the most widely used variant of stainless steel. They contain very low levels of carbon and high amounts of nickel and chromium, which are the main contributors to their formability, corrosion-resistance and wear-resistance. They are also non-magnetic in their annealed state but can become slightly magnetic when cold worked.

Austenitic stainless

steels are categorised in the 200 and 300 series in the AISI/SAE grade system,

which contain between 2% to 20% of nickel and between 16% to 30% of chromium.

The 300 series of austenitic stainless steels are chromium-nickel alloys, with

at least 8% nickel, which is the minimum amount required to convert all the

ferrite into austenite in an 18% chromium stainless steel.

The 200 series was

developed in the 1940s as an economical alternative to the 300 series. It was

developed to use nitrogen in addition to a lower amount of nickel at a time

when nickel was much more expensive and scarce.

304 stainless sheet is the most common and most widely used of

the nickel-based austenitic stainless steels. The grade 304 usually consists of

around 8% nickel and 18% chromium.

316 stainless sheet is another commonly used grade that has an

additional 2% of molybdenum which results in higher corrosion resistance.

The properties of austenitic stainless steel

Austenitic

stainless steels are characterised by their face-centred cubic (FCC) crystal

structure, which is attained when a sufficient quantity of austenitizing

elements such as nickel, manganese, carbon and nitrogen are added to the alloy

of iron and chromium.

Austenitic stainless

steels can be produced to be very soft with a yield strength of about 200 MPa

and they can be strengthened by cold working, which can raise the yield

strength by up to a factor of ten. Unlike ferritic alloys, they can retain

their ductility at cryogenic temperatures and their strength at high

temperatures.

Their

corrosion resistance can range from regular everyday use to highly specified

use such as in boiling seawater. Despite their superiority among stainless

steels, austenitic steels have inferior resistance to cyclic oxidation compared

to ferritic alloys and they are also susceptible to stress corrosion cracking.

The

endurance limit of austenitic steels is lower (~30% of their tensile strength)

than ferritic steels (~50 - 60% of their tensile strength) which means

they are more prone to fatigue failure.

Further,

austenitic stainless steels, with the addition of nickel, are suitable for low

temperature or cryogenic applications. Other elements such as silicon,

aluminium and niobium may be added to give the steel certain properties such as

resistance to halide pitting or oxidation. Sulphur or selenium can be added to

certain steel grades to improve their machinability

Due to the austenitic stainless steel being the most common type of

stainless steel, it also has the most applications—some of which include:

- Automobile parts

- Food and beverage equipment,

- Storage vessels and pipes for corrosive liquids

- Industrial equipment

- Different kinds of architecture

Martensitic

stainless steel (https://www.instagram.com/p/Cg1NlIjhwnl/?igshid=YmMyMTA2M2Y=)

Developed as a stainless steel that is resistant to corrosion while also

possible to strengthen through heat treatment, martensitic stainless steels are

basically alloys that are similar to carbon or low alloy steels with a

structure to ferritic steels. It has a body-centered tetragonal crystal

structure and is classified as a hard ferromagnetic group. It has incredibly

good ductility and toughness which decreases as its overall strength increases.

The strength that it gets from heat treatment depends on the carbon

content of the steels. Higher carbon content means higher potential strength

and hardness and lower ductility and toughness.

The properties of Martensitic stainless steel

The structures of martensitic stainless steels are

body centered tetragonal (bct) and they are classified as a hard ferro magnetic

group. In the annealed condition, these steels have tensile yield strengths of

around 275 N/sq mm and hence they can be machined, cold formed, or cold worked

in this condition. These stainless steels have good ductility and toughness

properties, which decrease as strength increases. Martensitic stainless steels

can be moderately hardened by cold working. These stainless steels are

typically heat treated by both hardening and tempering to yield strength levels

up to 1900 N/sq mm. The strength obtained by heat treatment depends on the

carbon content of the steels. Increasing the carbon content increases the

strength and hardness potential but decreases ductility and toughness. The

higher carbon grades are capable of being heat treated to a hardness of 60 HRC.

Martensitic stainless steels may be heat treated,

in a similar manner to conventional steels, to provide a range of mechanical

properties, but offer higher hardenability and have different heat treatment

temperatures. They are subject to an impact transition at low temperatures and

possess poor formability. Their thermal expansion and other thermal properties

are similar to conventional steels. They may be welded with caution when

matching filler metals are used but cracking can be a feature.

All

martensitic stainless steels are ferro magnetic. Due to the stresses induced by

the hardening transformation, these stainless steels exhibit permanent magnetic

properties if magnetized in the hardened condition. For a given grade, the

coercive force tends to increase with increasing hardness, rendering these

stainless steels more difficult to demagnetize. These stainless steels are not

used as permanent magnets to any significant extent.

Cold working increases the coercive force of these

steels changing their behaviour from that of a soft magnet to a weak permanent

magnet. If parts of cold worked martensitic stainless steel are exposed to a

strong magnetic field, the parts can be permanently magnetized and, therefore,

able to attract other ferro magnetic objects. Apart from possibly causing

handling problems, the parts would be able to attract bits of iron or steel

which will, if not removed, impair corrosion resistance. It is therefore

prudent to either electrically or thermally demagnetize such parts if they have

been subjected to a strong magnetic field during fabrication.

Martensitic stainless steels can be tested by

nondestructive testing using the magnetic particle inspection method,

unlike austenitic stainless steels.

Martensitic stainless steel, when compared to other types of stainless

steel has a relatively low profile—and its good tensile strength in combination

with moderate corrosion resistance and heat resistance makes it perfect for

these kinds of applications:

- Surgical equipment

- Dental equipment

- Wires, screws, springs, blades, and cutting tools

- Hydroelectric engines,

- Sporting equipment industry

Duplex stainless steel (https://www.instagram.com/p/Cg1NlIjhwnl/?igshid=YmMyMTA2M2Y=

)

Duplex stainless steel is a very useful metal that

is used the world over. It gets its name from the fact that it consists of two

different grades of metal.

Essentially, Duplex is a Fe-Ni-Cr alloy that has a

two-phase ferritic-austenitic stainless-steel microstructure when it is at room

temperature.

Duplex sheet are characterized by high chromium (19–28%)

and molybdenum (up to 5%) and lower nickel contents than austenitic stainless

steels. The most used duplex stainless steels are the 2205 (22% Chromium, 5%

Nickel) and the 2507 (25% Chromium, 7% Nickel); 2507 is known as “super duplex”

due to its higher resistance to corrosion.

The advantage of combining ferritic and austenitic

grades is that the resultant metal has a metallurgical structure that consists

of two phases and therefore benefits from the properties of both

microstructures.

These properties make duplex steel highly sought

after in heavy industries, like oil and gas nuclear and chemical processing.

Duplex stainless

steel has an array of various benefits such as:

· Strength: Duplex stainless steels have approximately double the strength of regular austenitic

or ferritic stainless steels.

·

Toughness

and ductility: Duplex stainless steels exceed the toughness and

ductility of ferritic grades although they are not as touch as austenitic

grades.

·

Corrosion resistance: As with all stainless steels, corrosion resistance

depends mostly on the composition of the stainless steel, with chromium,

molybdenum and nitrogen content being the most important. Duplex stainless

steels are extremely corrosion resistant and even in chloride and supplied environments, duplex stainless steels exhibit very high resistance to stress

corrosion cracking (SCC). SCC is a type of corrosion that takes place when a

particular set of factors are present: Tensile stress, corrosive

environment and a sufficiently high temperature.

·

Heat

Resistance: Duplex stainless steel has higher heat

conductivity and lower thermal expansion than austenitic steels. Duplex grades

can easily be used down to temperatures of at least -50°C because at low

temperatures they have better ductility that ferritic grades of steel.

· Cost: Duplex stainless steels have lower nickel and molybdenum contents than their

austenitic counterparts. This lower alloying content means that duplex

stainless steels can be lower in cost. Further to this, it is also possible

that the thickness of duplex stainless steel can be reduced as it has an

increased yield strength. Thinner products mean that significant weight savings

can be made.

·

Weldability: Duplex

stainless steels tend to have good weldability and all standard welding

processes can be used although they are not quite as easily welded as the

austenitic grades.

Applications

of Duplex

The extensive benefits of Duplex stainless steel

mean that it can be used in many different are used in:

·

Chemical processing, transport and storage

·

Pipes for production and transportation of oil and

gas

·

Oil and gas exploration and offshore rigs

·

Oil and gas refining

·

Marine environments

·

Pollution control equipment

·

Pulp & paper manufacturing

·

Chemical process plant

Precipitation

hardening stainless steel (https://www.instagram.com/p/Cg1NlIjhwnl/?igshid=YmMyMTA2M2Y=

)

Precipitation

hardening stainless steels are metals that have martensitic or semi-austenitic

properties and contain high percentages of chromium and nickel. These steels

are used in various industrial applications because of their high strength,

corrosion resistance and hardness. Precipitation hardening stainless steels get

their high tensile strength from undergoing a series of heat treatments. This

specialized heat treatment process includes the addition of Copper, Aluminum

and Titanium to enhance the steel’s corrosion resistance. Here’s everything you

need to know about precipitation hardening stainless steels:

STAINLESS STEEL

CLASSIFICATIONS

Precipitation hardening stainless steels are put into three groups based

on their properties after the heat treatments. These alloy groups are

martensitic, semi-austenitic and austenitic.

Austenitic Alloys: Austenitic stainless steels largely retain their

structure after the heat treatment process. The alloy should undergo annealing,

reheating and hardening treatments. The steel should be heated to no more than

2050 degrees Fahrenheit during the annealing procedure. Precipitation occurs

during the reheating process, which increases the hardness and strength of the

steel.

Martensitic Alloys: Martensitic stainless steels should be heated to no

more than 1950 degrees Fahrenheit during the annealing heating process. During

the cooling part of the process, this material undergoes a classification

transformation from austenite to martensite.

BENEFITS OF PRECIPITATION HARDENING

STAINLESS STEEL

One of the significant benefits of using precipitation hardening steels

is that they can be treated to take on many favorable properties. These

characteristics include:

Corrosion

Resistance: Precipitation hardening steels have greater

corrosion resistance than standard stainless steels, which is particularly

beneficial when the steel is used in an outdoor or extreme weather application.

The corrosion resistance of the steel can generally be enhanced during the heat

treatment process.

Formability:

Many grades of semi-austenitic stainless steel can be molded without any heat

treatments. On the other hand, martensitic stainless steels are tough both

before and after the heat treatment process and are therefore not easily

formed.

Weldability: Unlike

other stainless steel alloys, precipitation hardening steels can be readily

welded through standard fusion and resistance methods. Remember that special

care should be taken during the heat treatment process to ensure that the

optimum mechanical properties for weldability are achieved.

PRECIPITATION

HARDENING STAINLESS STEEL

Precipitation

hardening stainless steels are metals that have martensitic or semi-austenitic

properties and contain high percentages of chromium and nickel. These steels

are used in various industrial applications because of their high strength,

corrosion resistance and hardness. Precipitation hardening stainless steels get

their high tensile strength from undergoing a series of heat treatments. This

specialized heat treatment process includes the addition of Copper, Aluminum

and Titanium to enhance the steel’s corrosion resistance. Here’s everything you

need to know about precipitation hardening stainless steels

STAINLESS STEEL

CLASSIFICATIONS

Precipitation hardening stainless steels are put into three groups based

on their properties after the heat treatments. These alloy groups are

martensitic, semi-austenitic and austenitic.

Austenitic Alloys: Austenitic stainless steels largely retain their

structure after the heat treatment process. The alloy should undergo annealing,

reheating and hardening treatments. The steel should be heated to no more than

2050 degrees Fahrenheit during the annealing procedure. Precipitation occurs

during the reheating process, which increases the hardness and strength of the

steel.

Martensitic Alloys: Martensitic stainless steels should be heated to no

more than 1950 degrees Fahrenheit during the annealing heating process. During

the cooling part of the process, this material undergoes a classification

transformation from austenite to martensite.

PRECIPITATION

HARDENING STAINLESS STEEL APPLICATIONS

Because of the hardness and high tensile strength of this classification

of stainless steels, many applications are in the high technology or aerospace

engineering fields. These steels are used to manufacture the following

components:

·

Gears

·

Valves

·

Shafts

·

Specialized engine components

·

Turbine blades

· Molding dies

If you require stainless steel for whatever reason then contact Raisun Metal Zone Pvt. Ltd. https://www.raisunmetals.com/ or vizinox.com We are the manufacturer of stainless steel sheets and coils. we believe in quality service as well as a brilliant service to our customers.

Get in touch

Facebook :https://www.facebook.com/raisun.metals.5

Linkedin : https://www.linkedin.com/company/raisun-polywires-private-limited/

Youtube : https://youtube.com/channel/UCPaUVsNm-t4_sjfbffxf5Nw

Comments

Post a Comment